Polyurethane is new wonder material, which has superior properties, and plays a vital role in today’s industrial scenario, which combines strength of plastic and elasticity of rubber. Wire springs have tendency to break under high pressure and also have permanent set in short time. PU can sustain very high loads than rubber. Unlike rubber it does not take part in weathering or chemical actions under normal condition.

Applications:

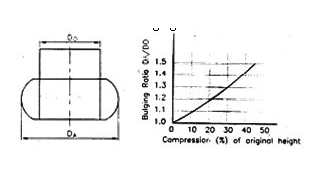

Elastomer springs cannot be compressed & therefore ample space should be left to accomodate their natural bulging action. The volume of deformation of length equals the volume of the bulge. Add to this figure a safety margin.

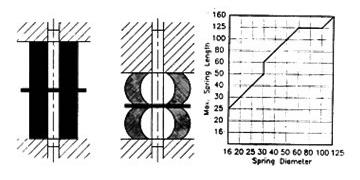

To obtain extended stroke lengths the springs can be used in series (stacking) The individual springs used in the stack has to be separated by spring washers. If all in the stack are equal the individual stroke, lengths are cumulative. Springs stacks have to be guided.

Application hints

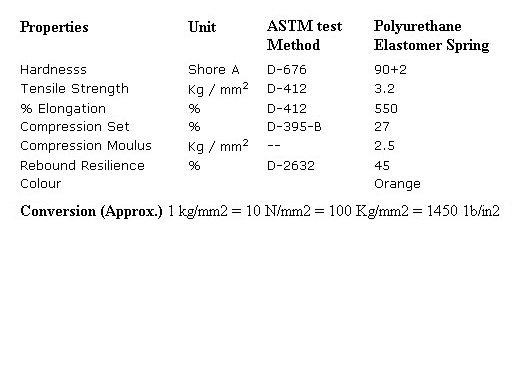

Elastomer springs Shore Hardness

Stroke (S) max 30%

Creep of original (Ss) 5-8 %

Spring Stroke (S)

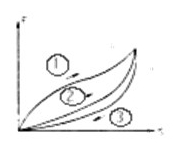

The maximum stroke in relation to the original height depends on the stroke frequency & it can be

inferred from the graph.

The creep factor of the height of the spring is determined by the ambient temperature and also by the spring material. The values given are based on practical results which have been reached up to 90% success under dynamic conditions after 10 cycles.

In order to ensure a positive spring response the spring will have to be preloaded by an amount > than the creep factor.

All elastomer springs tend to show variation caused by stiffness & as a result should be subjected to about 10

compression cycles before final use. The following graph represents values at 10 compression cycles under

static conditions. This conforms to DIN 9835, Page 1, Par

1. 1st Compression stroke

2. 10th Compression stroke

3. Return stroke for 1 & 2

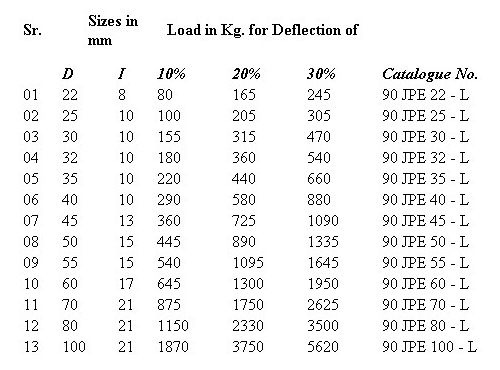

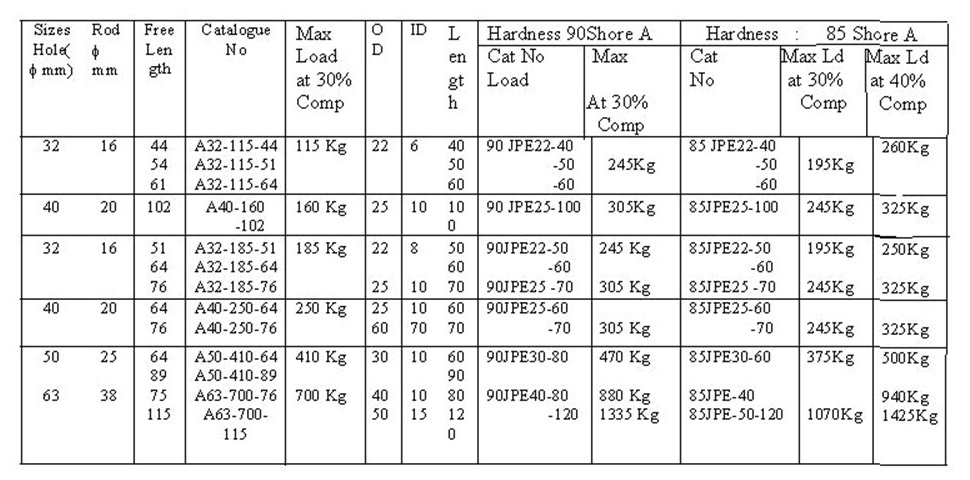

The comparison between steel springs & Polyurethane elastomer bushes used in sheet metal dies for reference see the Steel Specification chart

The table above shows the comparison between steel springs & Polyurethane elastomer bushes used in sheet metal dies. The table covers a range of load values & deflections in mm. As seen from the table, P.U. bushes have a definite advantage over the steel springs due to their higher load bearing compared to steel springs, which is in addition to their consistent performance & high life expectancy.